In regions like the Middle East and parts of Asia, businesses face extreme temperatures, often exceeding 45°C during the summer months. Air cooled chiller systems are increasingly becoming the go-to solution for industries that require reliable, energy-efficient cooling without the dependence on water resources. These systems provide scalable and sustainable options to keep operations running smoothly, even in the hottest climates.

The Need for Reliable Cooling in the UAE

The UAE’s desert climate presents unique challenges for industries that rely on temperature control. From data centers and healthcare facilities to hospitality and manufacturing, maintaining a consistent climate is crucial for operational efficiency, safety, and product quality. High temperatures can lead to equipment failure, reduced workforce productivity, and even safety hazards for workers.

Given the energy-intensive nature of cooling systems, businesses are increasingly seeking more sustainable and cost-effective solutions. Air cooled chillers offer a reliable, scalable solution to these challenges, providing high-performance cooling without relying on water resources.

Air Cooled Chillers: The Perfect Solution for UAE Businesses

Air cooled chillers are particularly well-suited for the UAE’s climate due to their energy efficiency and independence from water supplies. Unlike water-cooled systems that require a continuous water source, air cooled chillers use ambient air to cool the refrigerant, which reduces both water usage and operational costs.

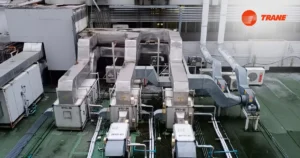

These systems are ideal for businesses that need scalable, flexible cooling, such as hotels, offices, and industrial facilities. Whether cooling large commercial spaces, manufacturing plants, or data centers, air cooled chillers can provide reliable performance throughout the year, especially during the peak summer months when temperatures soar.

Benefits of Air Cooled Chillers

Energy Efficiency

Air cooled chillers are known for their energy efficiency, a crucial factor in regions with high cooling demands. These systems use the surrounding air to cool the refrigerant, which reduces electricity consumption compared to traditional water-cooled systems. In areas where electricity costs are rising, the energy-saving benefits of air cooled chillers help businesses reduce operational expenses.

Low Maintenance

Compared to water-cooled systems, air cooled chillers are easier to maintain. These systems do not require water treatment, and their maintenance needs are minimal. This is especially beneficial in climates where water availability is a concern and the cost of maintaining a water-cooled system can be prohibitive.

Quick Deployment

Air cooled chillers can be deployed quickly and provide reliable, uninterrupted cooling without the need for significant downtime. Since these units don’t rely on water sources, they are easier to maintain and operate than traditional water-cooled systems, which require regular water treatment and maintenance.

In industries where downtime can lead to significant financial losses, air cooled chillers offer a quick and reliable cooling solution that ensures operations continue smoothly, even during extreme heat events.

Applications in Various Industries

Manufacturing and Industrial Applications

Manufacturing plants in regions like the Middle East often face harsh working conditions, which can lead to overheating of equipment and unsafe working environments. Air cooled chillers are deployed to keep machinery operating at optimal temperatures, ensuring efficiency and safety on the factory floor.

Healthcare

Hospitals and medical centers rely on precise cooling systems to maintain the proper conditions for medical equipment, medications, and patient care. Air cooled chillers offer a dependable, energy-efficient solution to ensure healthcare facilities can operate smoothly, even during extreme heat.

Data Centers

Data centers are highly sensitive to temperature changes, as overheating can lead to equipment failure and data loss. By using air cooled chillers, data centers can maintain the optimal temperature for their servers and networking equipment, ensuring that they remain operational and secure.